Food Production

As a result, Modified Atmosphere Packaging (MAP) is commonly adopted within the food industry, by where food products are packaged under a specified gaseous atmosphere.

MAP allows even smaller companies the opportunity to expand their geographic coverage, as by extending the shelf-life of their products they can export them further.

Costs for MAP are higher than traditional packaging, therefore testing is an advised requirement to ensure that expenses are justified.

Suitable packaging needs to be:

- Able to contain the product and any gases if packed under MAP

- Capable of withstanding the packaging and transportation process

- Suitably impermeable to water and gas vapour

- Capable of remaining airtightly sealed

Dynascan has experience of working with a range of food manufacturers, including those within the following sectors:

- Cheese and Dairy

- Meat

- Snacks – Crisps and Popcorn

- Confectionary

- Coffee

- Fruit and Vegetables

Food Production

All Dynascan package performance testing systems are manufactured under ISO 9001 accreditation and meet the requirements of many testing standards, including ASTM.

We have the ability to provide our customers with dedicated custom solutions or standard systems, dependent on specific requisites.

Please contact our experienced sales representatives to discuss your requirements further or request a free test report of your packaging integrity.

LeakVIEW Lite

- Extremely easy to operate and maintain

- Bubble emission and altitude simulation testing

- Dry vacuum burst testing

- Sensitive manual control

- Up to 750mbar of vacuum generated

- Requires only compressed air to operate

- Can detect leak holes down to 20µm

MediTEST

- No specialist tooling required

- Can detect leak holes down to 10µm

- Two, four or ten standard pack testers with other sizes available

- Stainless steel case work and CGMP compliance

- Advanced software for easy perimeter setup

- USB and RS232 for easy data retrieval or storage

- Short test cycle time

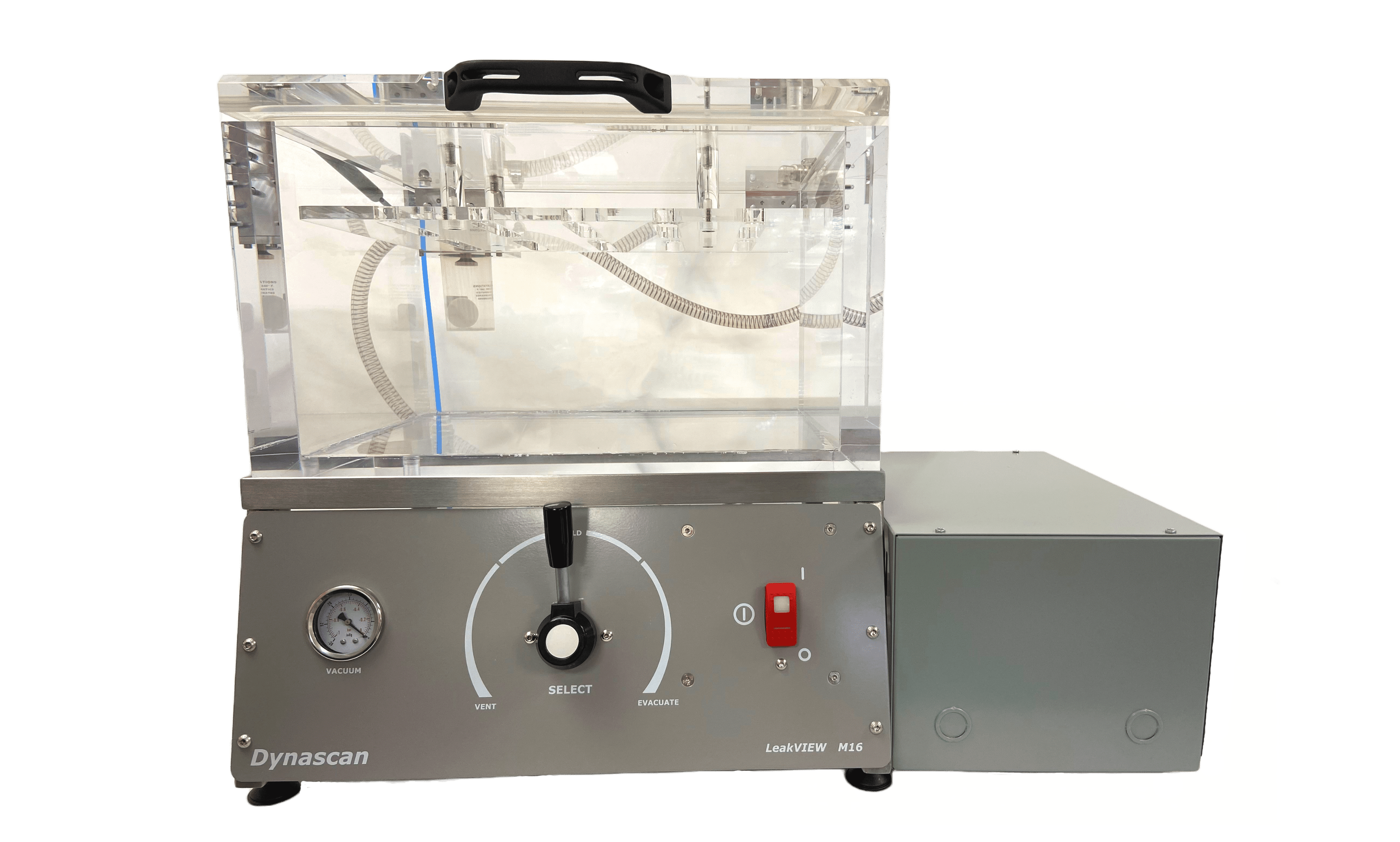

LeakVIEW

- Standard and custom size chambers available

- Bubble emission and altitude simulation testing

- Low maintenance

- Generally a stock item

- Automated or manual control

- No specialist tooling required

- Can detect leak holes down to 20µm

Get in touch

If you have any other questions or concerns then please get in touch and we will be happy to help.