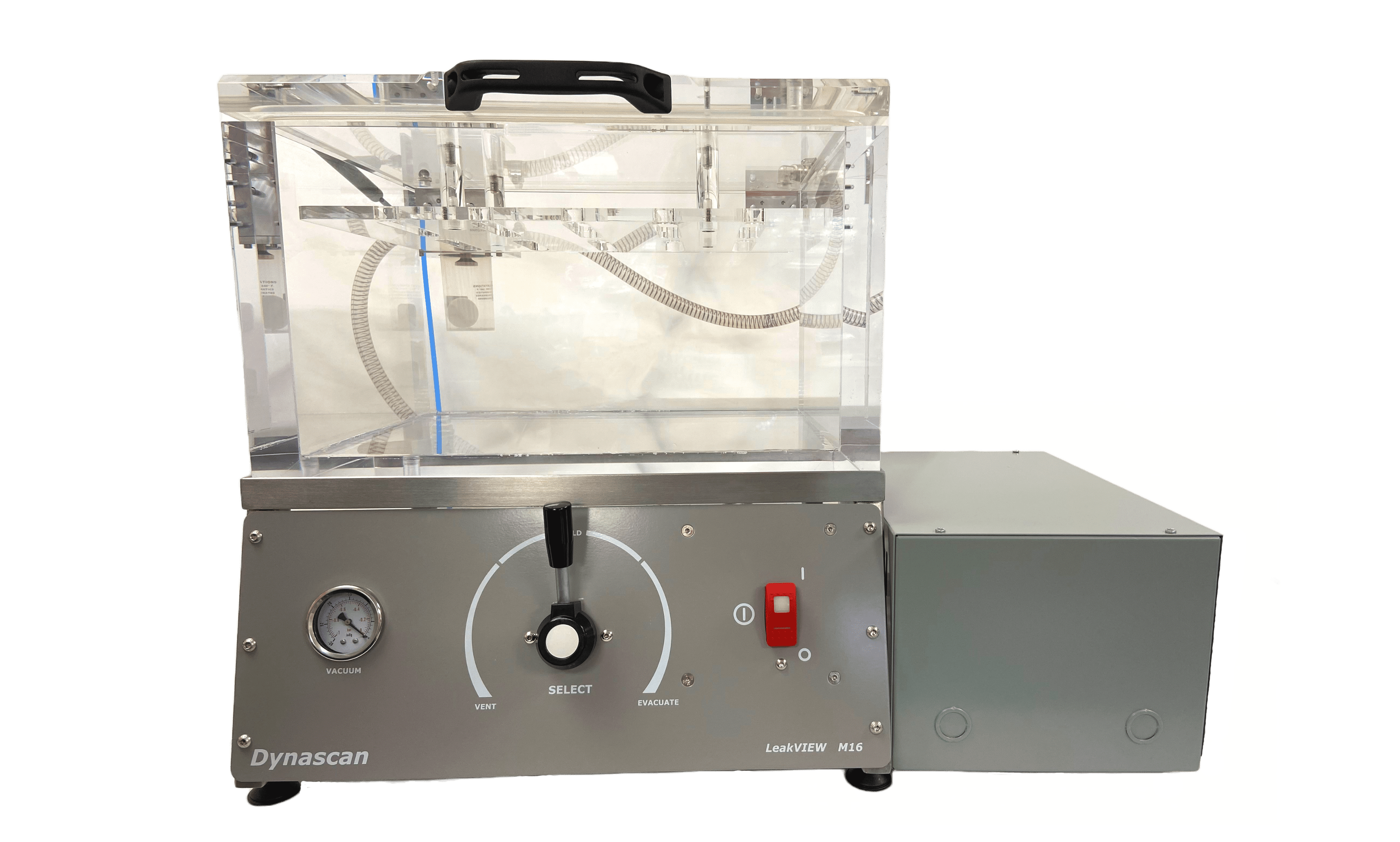

Dynascan LeakVIEW

Features

- Standard and custom size chambers available

- Bubble emission and altitude simulation testing

- Low maintenance

- Generically a stock item

- Automated or manual control

- No specialist tooling required

- Can detect holes down to 20µm

What our customers say:

“Dynascan. The first words that come in to mind now are, High quality, Brilliant and easy to work with machines. Customer service was also excellent, hassle free, from order to delivery and installation. Assisted us throughout the purchase up until installation, honest advise given to us and no delays”

Shehzad Dudhwala – Saraco Industries Ltd

Information

When carrying out bubble emissions testing the chamber is filled with water. During the test phase, the head-space is placed under a vacuum, causing the inserted packaging to inflate. Should any leaks be present, a stream of bubbles will be emitted. Water is not required for altitude simulation or burst testing.

The LeakVIEW range is available in two configurations, the Automatic and the Manual. Custom configurations are available to tailor the LeakVIEW to each individual’s requirements.

The LeakVIEW Programmable system is programmed from a colour touchscreen display for method development and can then be locked to prevent unauthorised changes. Automatic test cycles are initiated by a simple press of the start button. The display will indicate the end of the test cycle. In the case of altitude simulation, ascent and descent profiles can be displayed graphically.

Alternatively the LeakVIEW manual is operated by a simple Selector lever that rotates to hold the vacuum at a chosen level, and then further rotates to control the vent rate. No specialist tooling, electrical connection or calibration is required to operate the system.

An essential piece of equipment for any packaging facility, the LeakVIEW is fundamentally able to test any sealed packaging component with a head space.

Specifications

Bubble emission leak detection system Custom configurations available for chamber size and internal pressurisation

LeakVIEW Size 1 – (590mm x 540mm x 540mm), Weight 42kg empty, 67kg filled

LeakVIEW Size 2 – (670mm x 630mm x 600mm), Weight 65kg empty, 108kg filled

LeakVIEW Size 4 – (690mm x 690mm x 490mm), Weight 73kg empty, 123kg filled

LeakVIEW Size 5 – (690mm x 760mm x 590mm), Weight 94kg empty, 181kg filled

Programmable Controller Unit – (250mm x 450mm x 360mm), Weight 10kg

Please contact Dynascan for further information

Better than 20 microns hole diameter

Performance is a function of pack size, vacuum level and head space

Example

(Small Chamber)

0 to -800 mbar <30 seconds at 6 bar line pressure (empty)

0 to -200 mbar <5 seconds at 6 bar line pressure (empty)

LeakVIEW Manual Combination evacuation hold and vent control

LeakVIEW Programmable Touch screen and start stop reset button

0-11 bar pressure, 0-1 bar vacuum

Acrylic test chamber Grade 304 stainless steel base

LeakVIEW Manual Can operate in compliance with ASTM D3078 or ASTM F2096

LeakVIEW Programmable Can operate in compliance with ASTM D3078 or ASTM F2096

Directive 97/23/EC CAT S.E.P. applies

CE marked

Gauges may be verified for accuracy