Pharmaceutical

Pharmaceutical packaging must maintain its integrity from the point of manufacture to the delivery to customers or end users. Consumers are generally unable to detect product defects so the condition of the end product is imperative to its performance.

Additionally, sterility is a key requirement and great care is taken throughout the manufacturing process to eliminate physical, chemical and biological contamination. This must then be carried through to the packaging process.

Manufacturers must establish robust operating procedures to ensure that quality is built into each step of the process. Use of up-to-date technologies will safeguard against the production of poor quality products. Further information on viable testing methods can be found on our website.

Examples of pharmaceutical packaging that requires testing:

- Blister packs

- Filled sachets

- Vials and ampoules

- Speciality bags

- Pre-fillable syringes

- Medication tubes

- Pouches and strip packs

- Canisters

- Cartridges

Providing Dedicated Solutions

All Dynascan package performance testing systems are manufactured under ISO 9001 accreditation and meet the requirements of many testing standards, including ASTM.

We have the ability to provide our customers with dedicated custom solutions or standard systems, dependent on specific requisites.

Please contact our experienced sales representatives to discuss your requirements further or request a free test report of your packaging integrity.

LeakVIEW Lite

- Extremely easy to operate and maintain

- Bubble emission and altitude simulation testing

- Dry vacuum burst testing

- Sensitive manual control

- Up to 750mbar of vacuum generated

- Requires only compressed air to operate

- Can detect leak holes down to 20µm

MediBlue

- Simple to operate

- Low cost

- Pre-set test method

- Audio and visual indicators when test is complete

- Various test chamber sizes available to suit products

- Fully programmable version available

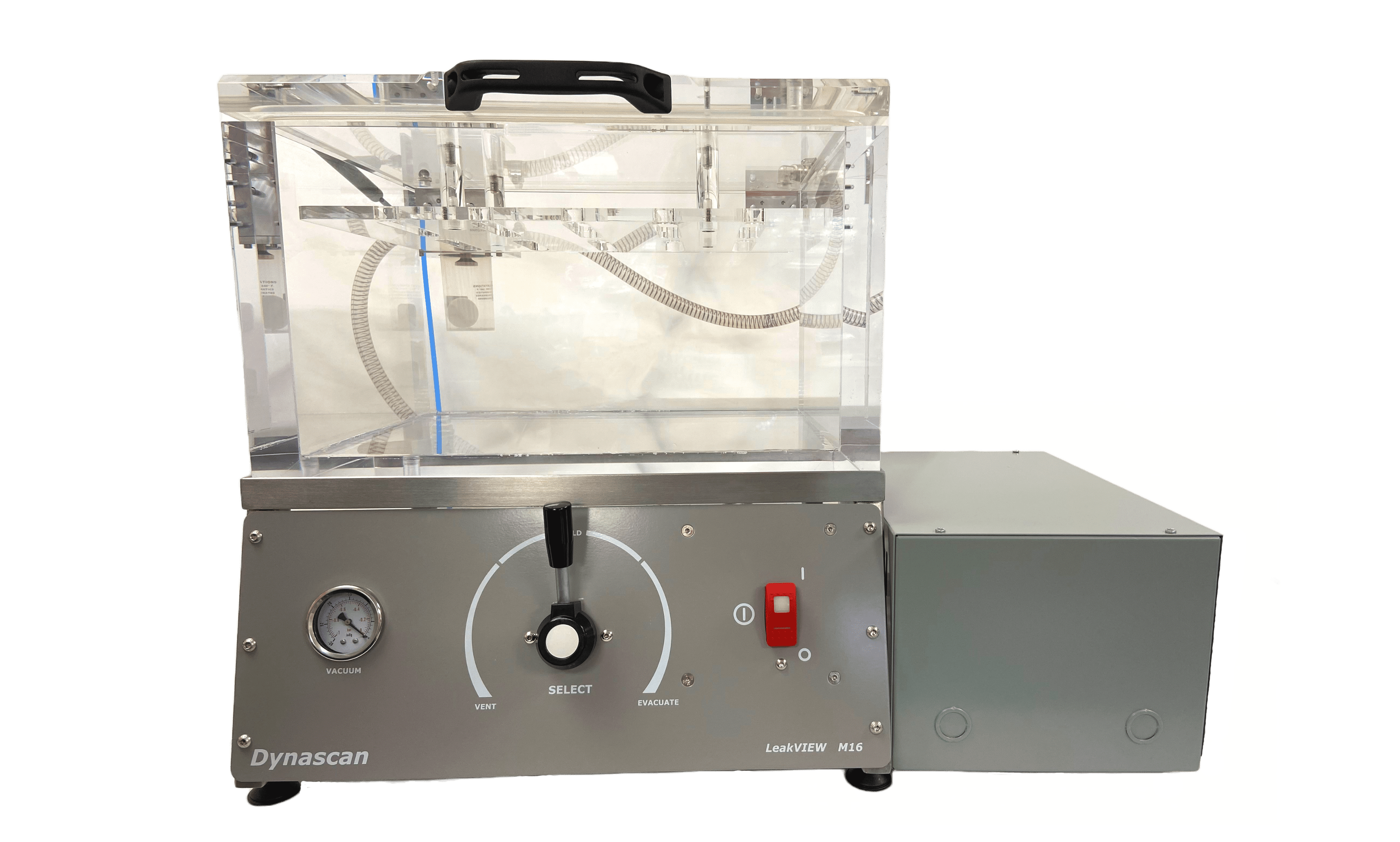

LeakVIEW

- Standard and custom size chambers available

- Bubble emission and altitude simulation testing

- Low maintenance

- Generally a stock item

- Automated or manual control

- No specialist tooling required

- Can detect leak holes down to 20µm

MediTest

- No specialist tooling required

- Can detect leak holes down to 10µm

- Two, four or ten standard pack testers with other sizes available

- Stainless steel case work and CGMP compliance

- Advanced software for easy perimeter setup

- USB and RS232 for easy data retrieval or storage

- Short test cycle time

Get in touch

If you have any other questions or concerns then please get in touch and we will be happy to help.